Tractor Power Take-Off (PTO) Shafts: The Heart of Sustainable Farming

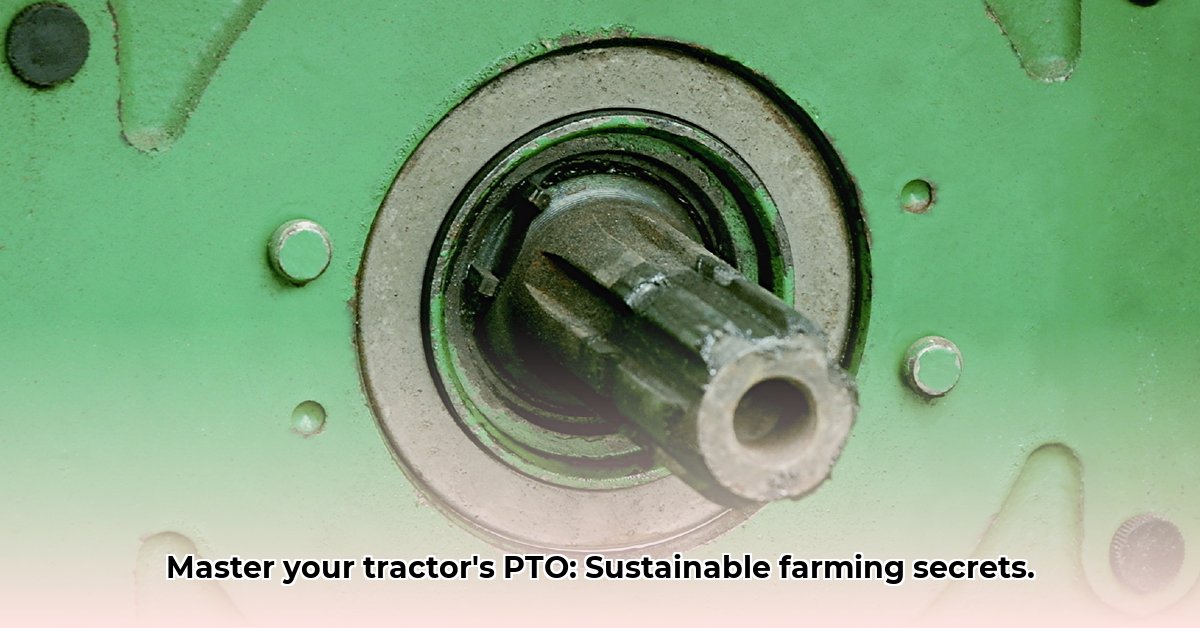

The power take-off (PTO) shaft, often overlooked, is a critical component for efficient and sustainable farming. This unsung hero connects your tractor's engine to various implements, powering essential tasks from tilling and mowing to baling and seeding. Understanding its function, maintenance, and role in resource management is crucial for environmentally conscious and profitable farming. Did you know that a well-maintained PTO shaft can significantly reduce fuel consumption, contributing directly to lower greenhouse gas emissions? For more information on PTO shaft parts, check out this helpful resource.

Decoding the Tractor PTO Shaft: Functionality and Mechanics

The PTO shaft acts as a high-strength rotating rod, transmitting power directly from your tractor's engine to implements. This mechanical connection enables efficient operation of various tools. The shaft's rotational force is transferred via a coupler, ensuring precise power delivery to the attached implement. This direct power transfer boosts efficiency compared to manual or less-powerful methods.

PTO Shaft Types: Choosing the Right Fit for Your Needs

PTO shafts are categorized primarily by their rotational speed: 540 RPM and 1000 RPM. The "RPM" (revolutions per minute) denotes the shaft's speed. Choosing the correct shaft is crucial for optimal performance and safety.

540 RPM PTO Shafts: The Versatile Powerhouse

These shafts provide high torque (rotational force), suitable for operations requiring significant pulling power. Applications include tilling heavy soil and powering hay balers. Their versatility makes them an excellent choice for diverse tasks.

1000 RPM PTO Shafts: High-Speed Efficiency

Spinning at a faster rate, 1000 RPM shafts are better for high-speed operations and less demanding tasks. They excel in applications like mowing, providing increased speed but lower torque compared to 540 RPM shafts. However, it's vital to remember that they may not be appropriate for all tasks.

Safety First: Essential Safeguards

Regardless of the RPM, safety is paramount. Modern PTO shafts incorporate safety features such as shear bolts or slip clutches. These act as protective mechanisms, preventing damage to equipment and injury to the operator in case of mishaps like hitting an obstruction. Always use the appropriate shaft type and implement combination. Mismatching them is hazardous and can lead to serious consequences.

PTO Shaft Maintenance: A Step-by-Step Guide

Regular maintenance ensures efficient operation and longevity. Following this simple checklist will help keep your PTO shaft in prime condition:

Regular Inspections (Weekly): Before each use, visually inspect the shaft for any anomalies: bends, cracks, excessive wear, or loose components. Addressing minor issues promptly prevents larger problems.

Lubrication (Monthly): Proper lubrication is critical. It reduces friction, wear, and tear, extending the shaft's lifespan. Consult your tractor's manual for recommended lubricants and a lubrication schedule. Consistent lubrication offers significant long-term benefits.

Safety Shield (Always): Never operate the PTO shaft without its safety shield. This vital protective barrier prevents entanglement and potential injury. The shield is non-negotiable for safe operation.

Storage (After Use): Store the shaft in a dry location, protecting it from the elements and potential damage. Proper storage ensures a long lifespan and prevents corrosion.

The PTO Shaft's Crucial Role in Sustainable Agriculture

The PTO shaft is more than just a mechanical connection; it's a key element in sustainable farming practices.

Fuel Efficiency: A well-maintained PTO shaft, matched to the appropriate implement, optimizes power transfer, resulting in reduced fuel consumption and lower greenhouse gas emissions.

Reduced Soil Compaction: Utilizing appropriate implements, such as no-till seeders, powered by the PTO reduces soil compaction, promoting soil health and minimizing environmental impact.

Optimized Implement Selection: Matching your implements to the correct PTO shaft speed maximizes efficiency and minimizes fuel use. Incorrect matching can overwork the engine and decrease productivity. Did you know that proper implement selection can lead to up to a 15% reduction in fuel consumption?

Selecting the Right Implement: Optimizing Performance

Choosing the right implement is just as crucial as maintaining the PTO shaft.

Compatibility: Ensure your implement is compatible with your tractor's PTO speed (540 or 1000 RPM). Improper matching can damage both implement and tractor.

Soil Type Awareness: Consider your soil type when choosing implements. Heavy-duty tillers for dense clay, lighter implements for sandy soils ensure optimal soil conservation.

Crop-Specific Implements: Selecting implements tailored to your crops maximize yield and overall efficiency. Investing in the right tools for the right task pays off significantly.

540 RPM vs. 1000 RPM: A Comparative Analysis

| Feature | 540 RPM PTO Shaft | 1000 RPM PTO Shaft |

|---|---|---|

| Speed | Slower speed, higher torque | Faster speed, lower torque |

| Applications | High-torque implements (e.g., tillers, balers) | High-speed operations (e.g., mowing) |

| Fuel Efficiency | Generally more fuel-efficient | Can be less fuel-efficient depending on the implement |

| Maintenance | Standard maintenance | Standard maintenance |

| Safety | Same safety precautions apply | Same safety precautions apply |

The optimal choice depends entirely on your specific farming practices and commonly used implements.

The Future of PTO Technology: Innovations on the Horizon

Continuous research aims to improve PTO shaft efficiency. New designs and materials are being explored to enhance power transmission and reduce wear. Staying abreast of these advancements will ensure access to the latest technologies for optimized farming.

Conclusion: Empowering Sustainable Farming Practices

The PTO shaft is more than just a connecting link; it is a fundamental component contributing to sustainable and efficient farming. Proper maintenance, correct implement selection, and an understanding of its functionality are key to maximizing its benefits for both your farm and the environment. Remember, a well-maintained PTO shaft is a significant investment in your farm's long-term success and environmental responsibility.